| Single Bellows Expansion Joints |

T.C.I manufactures single bellows expansion joints in 1-1/2" through 104" diameters. Bellows design follows EJMA (Expansion Joint Manufacturers Association) standards and all welding is in accordance with ASME Section IX. T-321 stainless steel is the most widely used material for bellows applications. DME can also design and form bellows in other alloys such as Inconel 625, Inconel 600, Inconel 825, Monel 400, Hastelloy C276, T-316-L stainless steel, T-304 stainless steel, T-310 stainless steel and many other alloys.

Non-standard and metric sizes can also be furnished by DME. We have an extensive range of tooling to meet most custom requirements. |

|

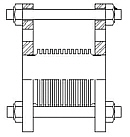

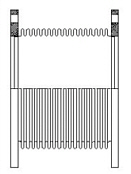

| Plate Flanged Single Bellows |

Economical plate flanges are drilled to ANSI B16.5 specifications with machined flat face finish. Raised faces are optional. Standard material is A-36 carbon steel with stainless steel and other alloys available. DME has complete machining capabilities to meet your custom flange requirements. |

|

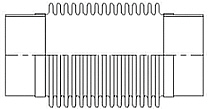

| Forged Flanged Single Bellows |

Forged flanges may be required to meet codes or elevated pressure requirements. A105 forged steel and A184 stainless raised face slip on flanges are available in 150#, 300#, 600#, and higher classes with many different flange facings.

|

|

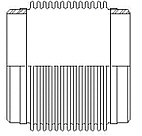

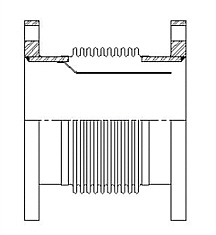

| Vanstone Flanged Single Bellows |

DME manufactures vanstone stub ends in a variety of materials and thickness. Stainless steel, Inconel, and Monel stubs can be used with carbon steel back up flanges. The flow media only contacts the bellows and stub ends.

|

|

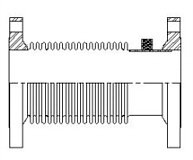

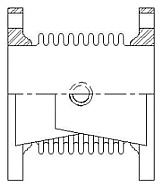

| Forged Lap Joint Flanged, Single Bellows |

High-pressure applications may not be able to use vanstone stub ends. Lap joint stub ends can also be furnished in many different alloys and pipe schedules.

|

|

| Plate Flanges With Tie Rods |

DME utilizes a triangular design on standard tie rod flanges. When (4) rods are required for pressure considerations, a square flange design is used. Standard flange drillings are to ANSI B16.5 specifications. Custom flanges are always available to meet customer requirements. |

|

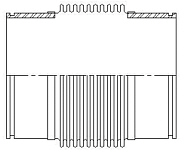

| Beveled Weld End Single Bellows |

Standard wall A53 carbon steel pipe is cut to any length and beveled for welding. Other pipe such as A106 GR B seamless, T-304 stainless steel, T-316 stainless steel and other exotic alloys can be furnished in all available pipe schedules. |

|

| Victaulic Groove Single Bellows |

Expansion joints can be fabricated with victaulic groove nipples for a "no weld" installation. The grooved pipe ends can be made in all available materials and alloys. |

|

A female NPT port is provided on the special 2-ply expansion joint. The outer ply contains the pressure if the inner ply fails and the pressure flows to the test port indicating a failure on customer's instrumentation. |

|

| Metric Flanged Single Bell |

DME has the ability to manufacture most metric size bellows. A well-equipped machine shop gives us the ability to make all metric size flanges in house. Re-using customer's metric flanges are always an economical option. |

|

DME manufactures a complete line of tube size bellows. Tube ends can be furnished in many alloys and wall thickness. In house seam welding equipment allows us to provide custom tubes without custom prices. |

|

| Flanged Bellows with Spacer Pipes |

With the use of pipe extensions, expansion joints can be made to required overall lengths. These joints can reduce the cost of additional modifications in the field. Pipe spacers also provide an area for optional flow liners to travel. |

|

| Flanged Bellows with Hinges |

Hinges permit angulation of the bellows in one plane only. This expansion joint does not require the use of main anchors when a pipe spool is placed between two hinged joints. Large amounts of lateral offset can be absorbed |